Pneumatic coal dust unloading gray ball valve

Pneumatic coal dust unloading gray ball valve

Nominal diameter: DN50 ~ 200mm

Nominal pressure: PN1.6 ~ 4.0MPa

Temperature: -28 ℃ ~ 300 ℃

Medium: lime, coal powder, soot, nitric acid, acetic acid

Main material: WCB, ZG1Cr18Ni9Ti, ZG1Cr18Ni12Mo2Ti

【Introduction】

FQ647M Pneumatic Pulverized Coal Dumping Ball Valve is an ideal equipment for controlling solid conveying such as pulverized coal and pulverized coal injection. It is widely used in blast furnace pulverized coal injection in metallurgy, ore dressing, electric power and other production processes. , Milling system and dust removal system in a variety of pipeline control.

Working principle

FQ647M pneumatic pulverized coal dusting ball valve with upper and lower stem fixed spool (shaft support) and movable seal seat design. Work more stable. With automatic compensation, two-way seal between the seat without backlash has a lot of shear and self-cleaning function. Especially for the Royal fiber and a small solid particles of suspension and viscous medium on-off. Adopting the straight-through structure, the flow passage is smooth, the phenomenon of fouling and clogging does not occur. The sealing pair is made of an alloy material. After special heat treatment, the valve is resistant to abrasion and abrasion while the valve eccentric spherical surface has the function of automatic compensation. So that the sealing pair in the case of a certain degree of wear and tear, still can achieve the effect of resealing. (Dusty gas, granular fluid).

【Features】

1, seat with automatic wear compensation device, more reliable to ensure the sealing performance of the ball valve.

2, the seal made of special materials, with high temperature, wear-resistant, long service life characteristics.

3, various forms of sealing Vice, according to different conditions can choose soft seal structure, hard seal structure, fire valve seat structure design.

4, according to the need to set grease-assisted seal structure, the valve seat and the stem part of the installation of grease injection valve, the emergency case can be temporarily sealed.

5, can be designed into anti-static structure, the ball and the stem, stem and valve body set between the conductive spring to avoid electrostatic ignition lit flammable substances, to ensure system safety.

6, the stem with the overall forging and modulation, hardness HB220 ~ 250, the stem with anti-blowing out the structural design, according to the need to lengthen the stem for buried places.

【Product Other Parameters】

Performance Specifications:

| Nominal diameter DN (mm) | 50 ~ 200 | ||||||

| Nominal pressure PN (MPa) | 1.6 | 2.5 | 4.0 | ||||

| Nominal pressure (MPa) | Strength test | 2.4 | 3.75 | 6.4 | |||

| Seal test | 1.8 | 2.75 | 4.4 | ||||

| Material material code | C | P | R | ||||

| The main parts | Body | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | |||

| Ball board | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | ||||

| Valve stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12Mo2Ti | ||||

| Sealing ring | Enhanced polytetrafluoroethylene para-benzene | ||||||

| filler | Teflon, flexible graphite | ||||||

| Applicable conditions | Suitable media | Lime, coal powder, coal ash | Nitric acids | Acetic acid | |||

| proper temperature | -28 ° C to 300 ° C | ||||||

| Actuator | model | GT or AW series | |||||

| Air pressure | 0.3-0.7MPa | ||||||

| Implementation standards | Design and manufacture | Structure length | Flange size | Pressure temperature | Test and test | ||

| GBT / 12237 | GB12221 | GB9113 | GB9131 | GB13927 | |||

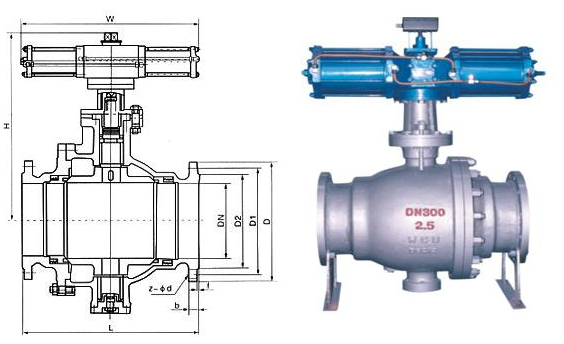

Installation Size Chart:

| Nominal diameter DN (mm) | Size (mm) | Actuator Model (for reference only) | |||||||||||||||

| 1.6MPa | 2.5MPa | 4.0MPa | |||||||||||||||

| L | D | D1 | B | Z-ΦD | L | D | D1 | B | Z-ΦD | L | D | D1 | B | Z-ΦD | 1.6, 2.5MPa | 4.0MPa | |

| 50 | 203 | 160 | 125 | 16 | 4-18 | 216 | 160 | 125 | 20 | 4-18 | 216 | 160 | 125 | 20 | 4-18 | GTD-80 | GTD-100 |

| 65 | 222 | 180 | 146 | 18 | 4-18 | 241 | 180 | 145 | twenty two | 8-18 | 241 | 180 | 145 | twenty two | 8-18 | GTD-100 | GTD-100 |

| 80 | 241 | 195 | 160 | 20 | 8-18 | 283 | 195 | 160 | twenty two | 8-18 | 283 | 195 | 160 | twenty two | 8-18 | GTD-100 | GTD-115 |

| 100 | 305 | 215 | 180 | 20 | 8-18 | 305 | 230 | 190 | twenty four | 8-23 | 305 | 230 | 190 | twenty four | 8-23 | GTD-115 | GTD-125 |

| 125 | 356 | 245 | 210 | twenty two | 8-18 | 381 | 270 | 220 | 28 | 8-25 | 381 | 270 | 220 | 28 | 8-25 | GTD-160 | AW13 |

| 150 | 394 | 280 | 240 | twenty four | 8-23 | 403 | 300 | 250 | 30 | 8-25 | 403 | 300 | 250 | 30 | 8-25 | GTD-90 | AW13 |

| 200 | 457 | 335 | 295 | 26 | 12-23 | 502 | 360 | 310 | 34 | 12-25 | 502 | 375 | 320 | 38 | 12-30 | AW17 | AW17 |

| 250 | 533 | 405 | 355 | 30 | 12-25 | 586 | 425 | 370 | 36 | 12-30 | AW17 | AW20 | |||||

| 300 | 610 | 460 | 410 | 30 | 12-25 | 648 | 485 | 430 | 40 | 16-30 | AW20 | AW20 | |||||

| 350 | 686 | 520 | 470 | 34 | 16-25 | 762 | 550 | 490 | 44 | 16-34 | AW20 | AW28 | |||||

| 400 | 762 | 580 | 525 | 36 | 16-30 | 838 | 610 | 550 | 48 | 16-34 | AW28 | AW28 | |||||

| 450 | 864 | 640 | 585 | 40 | 20-30 | 914 | 660 | 600 | 50 | 20-34 | AW28 | AW35 | |||||

| 500 | 914 | 705 | 650 | 44 | 20-34 | 991 | 730 | 660 | 52 | 20-41 | AW28 | AW35 | |||||