Electric ball valve principle, the principle of electric ball valve

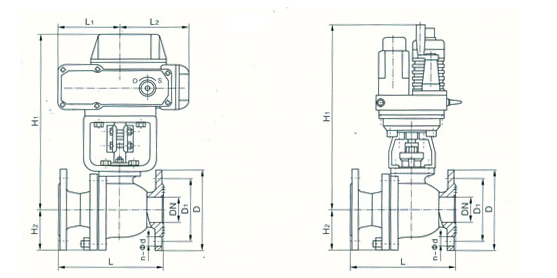

The electric ball valve is mainly composed of an electric actuator and a ball valve. The cock body is a sphere and has an action of rotating 90 degrees. Electric ball valve can not only cut off, cut off, cut off, turn off the flow of good products, or flow control system is the preferred product. The utility model has the advantages of high pressure resistance, temperature resistance, corrosion resistance, small flow resistance, long service life, wide application range, etc..

Operation principle of electric ball valve:

Electric ball valve mainly depends on the electric actuator to regulate the flow of electricity to operate the ball valve. Standard signal electric actuator input and output signals of 4-20mA and 220VAC power supply, motor drive worm gear set angle torque, to control the flow direction of the valve opening and closing media distribution and change or adjust the ratio of the degree of rotation of the spool, the valve opening and control fluid in proportion or percentage.

Application of electric ball valve:

Electric ball valve does not need manual operation, but intelligent operation. In the course of production, the environment and the site determine all factors. In high pressure, high temperature or low voltage, low temperature environment, the use of electric ball valve are different. We should pay attention to the following points:

1, for low temperature, low pressure, the material does not need to be adjusted too much.

2, in high pressure, high temperature circumstances, should choose to use high temperature and high pressure materials as electric ball valve materials, such as: stainless steel, alloy, this kind of material can withstand high pressure, high temperature.

3, electric ball valve, its internal parts need to be replaced to reduce the damage to the spool, but also conducive to medium flow, to avoid electric ball valve coking and clogging.

4, in the case of electric ball valve open, you can install some vibration avoidance machinery, to prevent the opening of the valve when the destruction of the internal structure of the valve.